推荐产品

轻触开关资讯

拨动开关资讯

检测开关资讯

贴片轻触开关出货报告范本

- 作者:G-Switch

- 发布时间:16-04-04 15:03

- 点击数:124

贴片轻触开关 检 验 报 告

报告编号: FOR1601056

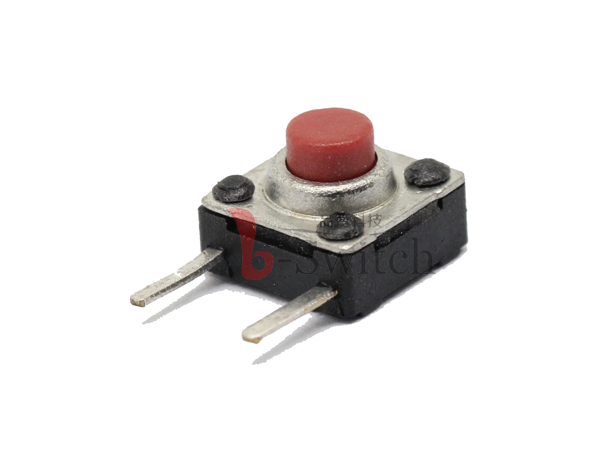

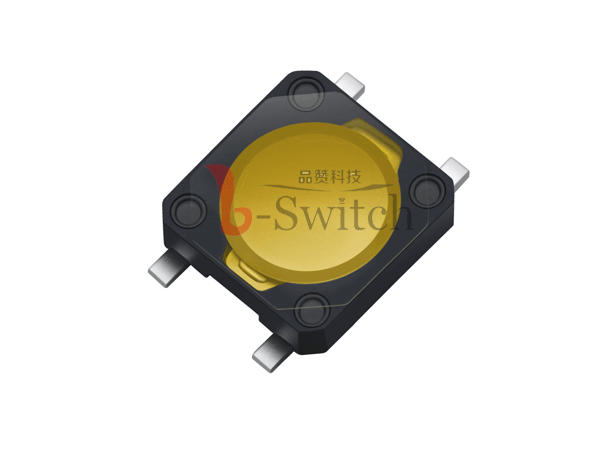

产品名称 TACT SWITCH 产品型号

产品规格 6X6 SMT

检验部门 质检部 检验地点 可靠性试验室

样本数量 100 只 样品等级 合格品

检验类别 可靠性试验检验 检验日期 2016.01.05-2016.01.06

检验依据

1.仕样书6.1 项 6.2 项 6.3 项 7.1 项

7.2 项

检验仪器、

设备

1.电阻仪 2. 绝缘电阻仪 3. 耐压测试仪 4.示波器

5.荷重曲线仪6、拉力器7、寿命测试仪8.高低温湿热试验箱

9.振动试验台 10.回流焊工作台 11.恒温箱 12.影像测量仪

检验结论

样品经试验,符合仕样书6.1项 6.2项 6.3项

7.1 项

7.2 项

本次样品检验合格。

备 注:此产品为高品质轻触开关

可靠性试验

报告编号: FOR1601056

1. Reliability test data(可靠性试验数据)

1.1Test for Contact Resistance 接触电阻试验

Condition: Measured at DC 12V 50mA or by ohmmeter allowing a small current at 1KHz

without any force.

条件:DC12V 50mA 为负载,并用1 千赫小电流接触电阻仪测量。

Standard: 100 m ohm max. 标准:最大100 m ohm

Test result data after examination:

Product No 1、 2、 3 、4 、5、 6 、7、 8 、9 、10。

Contact Resistance

(m ohm) 15 14 13 13 16 17 20 19 18 13

单项评价:符合仕样书第6.1.1 项,合格。

1.2Test for Insulation Resistance 绝缘电阻试验

Condition: DC 100V is applied between terminals and between terminal and cover for 1minute

±5seconds with a load of two times actuating force.

条件:在端子与端子之间,端子与外壳之间施加为1 分钟±5 秒带负载的致动力的两倍。

Standard: 100 M ohm min. 标准:最小100 M ohm

Test result data after examination:

Product No 1、 2 、3 、4、 5、 6、 7 、8 、9 、10。

Insulation Resistance

(M ohm) 103 、103 、103 、103 、103、 103、103 、103 、103、 103。

单项评价:符合仕样书第6.1.2 项,合格。

1.3Test for Dielectric Witstanding Voltage 电气耐压

AC 250 V (50Hz or60Hz) shall be applied between terminals and between individual terminals

and frame for one minute.

条件:在端子与端子之间,端子与外壳之间施加AC250V(50HZ-60HZ)的驱动力的两倍

Standard: There shall be no breakdown 标准:无击穿、无绝缘缺陷

Test result data after examination:

Product No 1 、2 、3、 4 、5、 6、 7 、8 、9、 10。

Dielectric

Witstanding Voltage

( V )

800 、800 、800、 800 、800、 800、 800、 800、 800、 800。

单项评价:符合仕样书第6.1.3 项,合格。

1.4Bounce 抖动

Lightly striking the center of the stem at a rate encountered in normal use (3 to 4 operations per

sec),Bounce shall be tested when “ON” and “OFF”.

在正常使用中(以每秒3-4 次周期)轻轻地在手柄中心加力,在通与断瞬间测试抖动

Product No 1 2 3 4 5 6 7 8 9 10

Bounce 4mS 5mS 4mS 5mS 4mS 4mS 4mS 6mS 4mS 4mS

单项评价:符合仕样书第6.1.4 项,合格。

1.5Actuating Force 动作力

Condition: Placing the switch such that the direction of switch operation is vertical and then

gradually increasing the load applied to the center of the stem, the maximum load required for

the stem to come to a stop shall be measured.

条件;开关的动作方向为垂直放置开关向推柄中心逐渐地增加负荷直到推柄停止时所测量的最大负荷

Standard: 250 ± 50 gf

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Actuating Force

(gf) 255 250 260 252 245 255 265 260 265 270

单项评价:符合仕样书第6.2.1 项,合格。

1.6Travel 行程

Condition: Placing the switch such that the direction of switch operation is vertical and then

applying a static load twice the actuating force to the center of the stem,the travel distance for

the stem to come to a stop shall be measured.

条件;开关的动作方向为垂直放置开关,并以双倍动作力的静负荷作用推柄中心,测量推柄从开始到停

止的行程距离

Standard: 0.25 ± 0.10 mm

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Travel

(mm) 0.23 0.23 0.24 0.22 0.21 0.22 0.23 0.22 0.23 0.22

单项评价:符合仕样书第6.2.2 项,合格。

1.7Return Force 返回力

Condition: The sample switch is installed such that the direction of switch operation is vertical

and,upon depression of the stem in its center the whole travel distance ,the force of the stem to

return to its free position shall be measured.

条件;开关的动作方向为垂直放置开关,在已有行程的推柄中心向上减小压力,推柄回到自由位置时所测

量到的力

Standard: 70 gf min

Product No 1 2 3 4 5 6 7 8 9 10

Return Force

( gf ) 90 86 85 80 92 87 95 100 90 110

Test result data after examination:

单项评价:符合仕样书第6.2.3 项,合格。

1.8Stop Strength 静止强度

Condition: Placing the switch such that the direction of switch operation is vertical,a static load

of 3 kgf shall be applied in the direction of stem operation for a period of 60 seconds.

条件;开关的动作方向为垂直放置开关,在推柄动作方向施加3KG 的静负荷,60 秒时间

Standard: There shall be no sign of damage mechanically and electrically.

标准:无机械的和电气的损伤迹象

Test result data after examination:

单项评价:符合 仕样书第6.2.4 项,合格。

1.9 Operating Life 动作寿命

Condition: Measurements shall be made following the test set forth below:

条件;按下列条件进行寿命试验

(1) DC 12V 50mA resistive load. DC 12V 50mA 阻性负载

(2) Rate of operation:2 to 3 operations per second 动作频率:2-3 次/每秒

(3) Cycles of operation: 10×104 cycles 动作次数: 10×104 cycles

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 14 16 15 17 15 17 16 15 17

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Volt ge ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 250 260 252 245 255 265 260 265 270

Travel

(mm) 0.20 0.22 0.21 0.20 0.24 0.21 0.23 0.22 0.24 0.21

Test result data after continued working10×104 cycles:

Product No 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 16 15 17 17 19 17 19 18 17 20

Insulation Resistance

(M ohm) 103 103 102 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 700 750 700 600 750 700 650 700 650 700

Actuating Force

(gf) 257 260 263 253 248 270 268 262 269 273

Travel

(mm) 0.21 0.24 0.22 0.23 0.25 0.21 0.23 0.25 0.22 0.24

单项评价:符合仕样书第6.3.1 项,合格。

2.0 Moisture Resistance 耐潮湿

Condition: Following the test set forth below the sample shall be left in normal temperature and

hhumidity conditions for one hour before measurements are made:

条件;样品按下列条件进行耐潮湿试验,测试前在正常温度和湿度条件下放置1 小时

(1) Temperature: 60±2℃ 温 度

(2) Relative hhumidity: 90 to 95% 相对湿度

(3) Time: 96 hours 时间

(4) Water drops shall be removed. 擦除水珠

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Dielec ricWitstandin

g Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 250 266 270 260 248 252 260 260 255

Travel

(mm) 0.24 0.23 0.24 0.22 0.22 0.23 0.21 0.25 0.22 0.24

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

DielectricWitstanding

Voltage ( V ) 700 750 650 650 750 700 700 750 700 700

Actuating Force

(gf) 260 255 260 245 260 255 252 270 260 265

Travel

(mm) 0.20 0.1

0.19 0.20 0.20 0.21 0.18 0.20 0.20 0.22

单项评价:符合仕样书第Item 6.3.2 项,合格。

2.1Resistance to Low Temperatures 耐低温

Condition: Placing the switch such that the direction of switch operation is vertical, the maximum

force to withstand a pull applied oppsite to the direction of stem operation shall be measured.

条件;样品按下列条件进行耐低温试验,测试前在正常温度和湿度条件下放置1 小时

(1) Temperature: -40±2℃ 温 度

(2) Time: 96 hours 时间

(3) Water drops shall be removed. 擦除水珠

Original data (before examination)

Pro uct No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 22 20 23 20 17 21 18 18 15 20

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 265 275 250 245 255 250 248 253 260 270

Travel

(mm) 0.24 0.23 0.24 0.22 0.22 0.23 0.21 0.25 0.22 0.24

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 20 18 20 20 21 18 19 21 20 17

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 270 275 260 264 275 270 268 255 260 270

Travel

(mm) 0.20 0.19 0.19 0.20 0.20 0.21 0.18 0.20 0.20 0.22

单项评价:符合仕样书第6.3.3 项,合格。

2.2 Heat Resistance 耐热

Condition: Following the test set forth below the sample shall be left in normal temperature and

humidity conditions for one hour before measurements are made:

条件;样品按下列条件进行耐热试验,测试前在正常温度和湿度条件下放置1 小时

(1) Temperature: 85±2℃ 温 度

(2) Time: 96 hours 时间

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 13 13 12 14 14 13 12 12 14

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 250 270 257 280 275 274 265 260 254 255

Travel

(mm) 0.21 0.22 0.20 0.21 0.21 0.22 0.24 0.22 0.23 0.25

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 14 12 13 15 15 14 14 13 15

Insulation Resistance

(M ohm) 103 103 102 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 700 750 700 600 750 700 650 700 650 700

Actuating Force

(gf) 250 253 260 276 270 283 270 266 260 263

Travel

(mm) 0.22 0.21 0.20 0.21 0.20 0.22 0.21 0.22 0.23 0.23

单项评价:符合 仕样书第6.3.4 项,合格。

2.3 Change of Temperature 温度循环

Condition: Following the test set forth below the sample shall be left in normal temperature and

humidity conditions for one hour before measurements are made:

条件;样品按下列条件进行温度循环试验,测试前在正常温度和湿度条件下放置1 小时

(1) The highest temperature: 85±2℃

(2) The minimum temperature: -40±2℃

(3) One cycles: six hours 一周期6 小时

(4)Cycling:Five cycles 周期: 5 次

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 13 11 13 12 11 13 14 15 13 15

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 260 260 260 276 270 283 270 278 260 250

Travel

(mm) 0.22 0.21 0.20 0.21 0.23 0.20 0.22 0.21 0.23 0.21

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 13 15 15 17 16 16 17 15 17

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 265 270 273 254 276 260 278 270 255

Travel

(mm) 0.21 0.20 0.20 0.21 0.24 0.20 0.23 0.21 0.23 0.22

单项评价:符合仕样书第6.3.5 项,合格

2.4 Salt Spray Test 盐雾试验

The salt spray test shall be conducted at the following conditions :

条件:样品按下列条件进行盐雾试验

(1)Density(浓度): 溶液(5±1)% Nacl (质量百分比)

(2)Temperature: 35±2℃ 温度

(3) Time: 24 hours 时间 金属件无发黄、生锈

单项评价:符合仕样书第6. 3.6 项,合格

2.5 Vibration Resistance 耐振动

Condition: Measurements shall be made following the test set forth below:

按下列条件进行抗振动试验

(1)Range of oscillation:10 to 55Hz 频率范围

(2)Amplitude,pk-to-pk:1.5 mm 振幅: 峰-峰1.5mm

(3)Cycle of sweep: 10-55-10Hz in one minute,approx.

扫描周期: 10-55-10Hz 约一分钟内

(4)Mode of sweep :Logarithmically sweep or uniform sweep. 扫描方式:对数扫描式恒定扫描

(5)Direction of oscillation: 振动方向

Three mutually perpendicular directions,including the directionof stem travel.

3 个相互垂直方向,包括推柄行程方向

(6)Duration of testing: 持续时间

2 hours each ,for a total of 6hours.每方向2 小时.共6 小时

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 17 15 15 14 15 13 11 14 11 12

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 250 260 265 270 255 266 270 266 249 260

Travel

(mm) 0.23 0.21 0.20 0.21 0.22 0.23 0.22 0.21 0.21 0.21

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 18 16 14 13 13 15 12 12 14 15

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 260 275 270 257 270 255 260 256 265

Travel

(mm) 0.20 0.19 0.20 0.21 0.22 0.23 0.22 0.21 0.21 0.21

单项评价:符合仕样书第6. 3.7 项,合格

2.6 Impact Shock Resistance 抗冲击

Condition: Measurements shall be made following the test set forth below:

按下列条件进行冲击试验

(1)Acceleration:80g 加速度

(2)Cycles of test :3 cycles each in 6directions, for a total of 18cycles

试验次数:每个方向3 次,6 个方向共18 次

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 16 15 14 15 17 16 14 13 14 12

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 250 275 280 270 257 266 255 260 262 275

Travel

(mm) 0.23 0.22 0.22 0.21 0.24 0.22 0.25 0.21 0.21 0.20

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 17 16 15 16 15 17 15 15 14 13

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 270 260 255 275 266 255 260 266 257

Travel

(mm) 0.23 0.23 0.23 0.22 0.21 0.22 0.22 0.22 0.23 0.24

单项评价:符合仕样书第6.3.8 项,合格

2.7 Solderability 焊接性

Electric soldering iron Temperature:250℃±5℃,Time: 4S±1S Tin Area:90%

电焊铁温度:250℃±5℃ 时间:4 秒±1 秒 焊接面积90%以上

Product No 1 2 3 4 5 6 7 8 9 10

Solderability 97% 96% 95% 97% 97% 95% 95% 94% 94% 95%

单项评价:符合规格书第7.1 项,合格。

2.8 Patience high temperature 焊接耐热性

Preheat: Temperature on the copper foil surface should reach 180℃, 2±0.3 minutes after

The P.W.B entered into the soldering equipment

预热:在P.W.B(印刷线路板)进入焊接设备后,2±0.3 分钟内铜箔表面要达到180℃

Soldering heat: Temperature on the copper foil surface should reach the peak temperature of

260℃ within 3 seconds after the P.B.W entered into soldering heat zone.

焊接温度: 在 P.W.B(印刷线路板)进入焊接温区3 秒内,铜箔表面达到峰值温度260℃

Product No 1 2 3 4 5 6 7 8 9 10

patience high temperature OK OK OK OK OK OK OK OK OK OK

单项评价:符合规格书第7.2 项,合格。

报告编号: FOR1601056

产品名称 TACT SWITCH 产品型号

产品规格 6X6 SMT

检验部门 质检部 检验地点 可靠性试验室

样本数量 100 只 样品等级 合格品

检验类别 可靠性试验检验 检验日期 2016.01.05-2016.01.06

检验依据

1.仕样书6.1 项 6.2 项 6.3 项 7.1 项

7.2 项

检验仪器、

设备

1.电阻仪 2. 绝缘电阻仪 3. 耐压测试仪 4.示波器

5.荷重曲线仪6、拉力器7、寿命测试仪8.高低温湿热试验箱

9.振动试验台 10.回流焊工作台 11.恒温箱 12.影像测量仪

检验结论

样品经试验,符合仕样书6.1项 6.2项 6.3项

7.1 项

7.2 项

本次样品检验合格。

备 注:此产品为高品质轻触开关

可靠性试验

报告编号: FOR1601056

1. Reliability test data(可靠性试验数据)

1.1Test for Contact Resistance 接触电阻试验

Condition: Measured at DC 12V 50mA or by ohmmeter allowing a small current at 1KHz

without any force.

条件:DC12V 50mA 为负载,并用1 千赫小电流接触电阻仪测量。

Standard: 100 m ohm max. 标准:最大100 m ohm

Test result data after examination:

Product No 1、 2、 3 、4 、5、 6 、7、 8 、9 、10。

Contact Resistance

(m ohm) 15 14 13 13 16 17 20 19 18 13

单项评价:符合仕样书第6.1.1 项,合格。

1.2Test for Insulation Resistance 绝缘电阻试验

Condition: DC 100V is applied between terminals and between terminal and cover for 1minute

±5seconds with a load of two times actuating force.

条件:在端子与端子之间,端子与外壳之间施加为1 分钟±5 秒带负载的致动力的两倍。

Standard: 100 M ohm min. 标准:最小100 M ohm

Test result data after examination:

Product No 1、 2 、3 、4、 5、 6、 7 、8 、9 、10。

Insulation Resistance

(M ohm) 103 、103 、103 、103 、103、 103、103 、103 、103、 103。

单项评价:符合仕样书第6.1.2 项,合格。

1.3Test for Dielectric Witstanding Voltage 电气耐压

AC 250 V (50Hz or60Hz) shall be applied between terminals and between individual terminals

and frame for one minute.

条件:在端子与端子之间,端子与外壳之间施加AC250V(50HZ-60HZ)的驱动力的两倍

Standard: There shall be no breakdown 标准:无击穿、无绝缘缺陷

Test result data after examination:

Product No 1 、2 、3、 4 、5、 6、 7 、8 、9、 10。

Dielectric

Witstanding Voltage

( V )

800 、800 、800、 800 、800、 800、 800、 800、 800、 800。

单项评价:符合仕样书第6.1.3 项,合格。

1.4Bounce 抖动

Lightly striking the center of the stem at a rate encountered in normal use (3 to 4 operations per

sec),Bounce shall be tested when “ON” and “OFF”.

在正常使用中(以每秒3-4 次周期)轻轻地在手柄中心加力,在通与断瞬间测试抖动

Product No 1 2 3 4 5 6 7 8 9 10

Bounce 4mS 5mS 4mS 5mS 4mS 4mS 4mS 6mS 4mS 4mS

单项评价:符合仕样书第6.1.4 项,合格。

1.5Actuating Force 动作力

Condition: Placing the switch such that the direction of switch operation is vertical and then

gradually increasing the load applied to the center of the stem, the maximum load required for

the stem to come to a stop shall be measured.

条件;开关的动作方向为垂直放置开关向推柄中心逐渐地增加负荷直到推柄停止时所测量的最大负荷

Standard: 250 ± 50 gf

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Actuating Force

(gf) 255 250 260 252 245 255 265 260 265 270

单项评价:符合仕样书第6.2.1 项,合格。

1.6Travel 行程

Condition: Placing the switch such that the direction of switch operation is vertical and then

applying a static load twice the actuating force to the center of the stem,the travel distance for

the stem to come to a stop shall be measured.

条件;开关的动作方向为垂直放置开关,并以双倍动作力的静负荷作用推柄中心,测量推柄从开始到停

止的行程距离

Standard: 0.25 ± 0.10 mm

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Travel

(mm) 0.23 0.23 0.24 0.22 0.21 0.22 0.23 0.22 0.23 0.22

单项评价:符合仕样书第6.2.2 项,合格。

1.7Return Force 返回力

Condition: The sample switch is installed such that the direction of switch operation is vertical

and,upon depression of the stem in its center the whole travel distance ,the force of the stem to

return to its free position shall be measured.

条件;开关的动作方向为垂直放置开关,在已有行程的推柄中心向上减小压力,推柄回到自由位置时所测

量到的力

Standard: 70 gf min

Product No 1 2 3 4 5 6 7 8 9 10

Return Force

( gf ) 90 86 85 80 92 87 95 100 90 110

Test result data after examination:

单项评价:符合仕样书第6.2.3 项,合格。

1.8Stop Strength 静止强度

Condition: Placing the switch such that the direction of switch operation is vertical,a static load

of 3 kgf shall be applied in the direction of stem operation for a period of 60 seconds.

条件;开关的动作方向为垂直放置开关,在推柄动作方向施加3KG 的静负荷,60 秒时间

Standard: There shall be no sign of damage mechanically and electrically.

标准:无机械的和电气的损伤迹象

Test result data after examination:

单项评价:符合 仕样书第6.2.4 项,合格。

1.9 Operating Life 动作寿命

Condition: Measurements shall be made following the test set forth below:

条件;按下列条件进行寿命试验

(1) DC 12V 50mA resistive load. DC 12V 50mA 阻性负载

(2) Rate of operation:2 to 3 operations per second 动作频率:2-3 次/每秒

(3) Cycles of operation: 10×104 cycles 动作次数: 10×104 cycles

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 14 16 15 17 15 17 16 15 17

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Volt ge ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 250 260 252 245 255 265 260 265 270

Travel

(mm) 0.20 0.22 0.21 0.20 0.24 0.21 0.23 0.22 0.24 0.21

Test result data after continued working10×104 cycles:

Product No 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 16 15 17 17 19 17 19 18 17 20

Insulation Resistance

(M ohm) 103 103 102 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 700 750 700 600 750 700 650 700 650 700

Actuating Force

(gf) 257 260 263 253 248 270 268 262 269 273

Travel

(mm) 0.21 0.24 0.22 0.23 0.25 0.21 0.23 0.25 0.22 0.24

单项评价:符合仕样书第6.3.1 项,合格。

2.0 Moisture Resistance 耐潮湿

Condition: Following the test set forth below the sample shall be left in normal temperature and

hhumidity conditions for one hour before measurements are made:

条件;样品按下列条件进行耐潮湿试验,测试前在正常温度和湿度条件下放置1 小时

(1) Temperature: 60±2℃ 温 度

(2) Relative hhumidity: 90 to 95% 相对湿度

(3) Time: 96 hours 时间

(4) Water drops shall be removed. 擦除水珠

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Dielec ricWitstandin

g Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 250 266 270 260 248 252 260 260 255

Travel

(mm) 0.24 0.23 0.24 0.22 0.22 0.23 0.21 0.25 0.22 0.24

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

DielectricWitstanding

Voltage ( V ) 700 750 650 650 750 700 700 750 700 700

Actuating Force

(gf) 260 255 260 245 260 255 252 270 260 265

Travel

(mm) 0.20 0.1

0.19 0.20 0.20 0.21 0.18 0.20 0.20 0.22

单项评价:符合仕样书第Item 6.3.2 项,合格。

2.1Resistance to Low Temperatures 耐低温

Condition: Placing the switch such that the direction of switch operation is vertical, the maximum

force to withstand a pull applied oppsite to the direction of stem operation shall be measured.

条件;样品按下列条件进行耐低温试验,测试前在正常温度和湿度条件下放置1 小时

(1) Temperature: -40±2℃ 温 度

(2) Time: 96 hours 时间

(3) Water drops shall be removed. 擦除水珠

Original data (before examination)

Pro uct No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 22 20 23 20 17 21 18 18 15 20

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 265 275 250 245 255 250 248 253 260 270

Travel

(mm) 0.24 0.23 0.24 0.22 0.22 0.23 0.21 0.25 0.22 0.24

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 20 18 20 20 21 18 19 21 20 17

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 270 275 260 264 275 270 268 255 260 270

Travel

(mm) 0.20 0.19 0.19 0.20 0.20 0.21 0.18 0.20 0.20 0.22

单项评价:符合仕样书第6.3.3 项,合格。

2.2 Heat Resistance 耐热

Condition: Following the test set forth below the sample shall be left in normal temperature and

humidity conditions for one hour before measurements are made:

条件;样品按下列条件进行耐热试验,测试前在正常温度和湿度条件下放置1 小时

(1) Temperature: 85±2℃ 温 度

(2) Time: 96 hours 时间

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 13 13 12 14 14 13 12 12 14

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 250 270 257 280 275 274 265 260 254 255

Travel

(mm) 0.21 0.22 0.20 0.21 0.21 0.22 0.24 0.22 0.23 0.25

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 14 12 13 15 15 14 14 13 15

Insulation Resistance

(M ohm) 103 103 102 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 700 750 700 600 750 700 650 700 650 700

Actuating Force

(gf) 250 253 260 276 270 283 270 266 260 263

Travel

(mm) 0.22 0.21 0.20 0.21 0.20 0.22 0.21 0.22 0.23 0.23

单项评价:符合 仕样书第6.3.4 项,合格。

2.3 Change of Temperature 温度循环

Condition: Following the test set forth below the sample shall be left in normal temperature and

humidity conditions for one hour before measurements are made:

条件;样品按下列条件进行温度循环试验,测试前在正常温度和湿度条件下放置1 小时

(1) The highest temperature: 85±2℃

(2) The minimum temperature: -40±2℃

(3) One cycles: six hours 一周期6 小时

(4)Cycling:Five cycles 周期: 5 次

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 13 11 13 12 11 13 14 15 13 15

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 260 260 260 276 270 283 270 278 260 250

Travel

(mm) 0.22 0.21 0.20 0.21 0.23 0.20 0.22 0.21 0.23 0.21

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 15 13 15 15 17 16 16 17 15 17

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 265 270 273 254 276 260 278 270 255

Travel

(mm) 0.21 0.20 0.20 0.21 0.24 0.20 0.23 0.21 0.23 0.22

单项评价:符合仕样书第6.3.5 项,合格

2.4 Salt Spray Test 盐雾试验

The salt spray test shall be conducted at the following conditions :

条件:样品按下列条件进行盐雾试验

(1)Density(浓度): 溶液(5±1)% Nacl (质量百分比)

(2)Temperature: 35±2℃ 温度

(3) Time: 24 hours 时间 金属件无发黄、生锈

单项评价:符合仕样书第6. 3.6 项,合格

2.5 Vibration Resistance 耐振动

Condition: Measurements shall be made following the test set forth below:

按下列条件进行抗振动试验

(1)Range of oscillation:10 to 55Hz 频率范围

(2)Amplitude,pk-to-pk:1.5 mm 振幅: 峰-峰1.5mm

(3)Cycle of sweep: 10-55-10Hz in one minute,approx.

扫描周期: 10-55-10Hz 约一分钟内

(4)Mode of sweep :Logarithmically sweep or uniform sweep. 扫描方式:对数扫描式恒定扫描

(5)Direction of oscillation: 振动方向

Three mutually perpendicular directions,including the directionof stem travel.

3 个相互垂直方向,包括推柄行程方向

(6)Duration of testing: 持续时间

2 hours each ,for a total of 6hours.每方向2 小时.共6 小时

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 17 15 15 14 15 13 11 14 11 12

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 250 260 265 270 255 266 270 266 249 260

Travel

(mm) 0.23 0.21 0.20 0.21 0.22 0.23 0.22 0.21 0.21 0.21

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 18 16 14 13 13 15 12 12 14 15

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 260 275 270 257 270 255 260 256 265

Travel

(mm) 0.20 0.19 0.20 0.21 0.22 0.23 0.22 0.21 0.21 0.21

单项评价:符合仕样书第6. 3.7 项,合格

2.6 Impact Shock Resistance 抗冲击

Condition: Measurements shall be made following the test set forth below:

按下列条件进行冲击试验

(1)Acceleration:80g 加速度

(2)Cycles of test :3 cycles each in 6directions, for a total of 18cycles

试验次数:每个方向3 次,6 个方向共18 次

Original data (before examination)

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 16 15 14 15 17 16 14 13 14 12

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 250 275 280 270 257 266 255 260 262 275

Travel

(mm) 0.23 0.22 0.22 0.21 0.24 0.22 0.25 0.21 0.21 0.20

Test result data after examination:

Product No 1 2 3 4 5 6 7 8 9 10

Contact Resistance

(m ohm) 17 16 15 16 15 17 15 15 14 13

Insulation Resistance

(M ohm) 103 103 103 103 103 103 103 103 103 103

DielectricWitstanding

Voltage ( V ) 800 800 800 800 800 800 800 800 800 800

Actuating Force

(gf) 255 270 260 255 275 266 255 260 266 257

Travel

(mm) 0.23 0.23 0.23 0.22 0.21 0.22 0.22 0.22 0.23 0.24

单项评价:符合仕样书第6.3.8 项,合格

2.7 Solderability 焊接性

Electric soldering iron Temperature:250℃±5℃,Time: 4S±1S Tin Area:90%

电焊铁温度:250℃±5℃ 时间:4 秒±1 秒 焊接面积90%以上

Product No 1 2 3 4 5 6 7 8 9 10

Solderability 97% 96% 95% 97% 97% 95% 95% 94% 94% 95%

单项评价:符合规格书第7.1 项,合格。

2.8 Patience high temperature 焊接耐热性

Preheat: Temperature on the copper foil surface should reach 180℃, 2±0.3 minutes after

The P.W.B entered into the soldering equipment

预热:在P.W.B(印刷线路板)进入焊接设备后,2±0.3 分钟内铜箔表面要达到180℃

Soldering heat: Temperature on the copper foil surface should reach the peak temperature of

260℃ within 3 seconds after the P.B.W entered into soldering heat zone.

焊接温度: 在 P.W.B(印刷线路板)进入焊接温区3 秒内,铜箔表面达到峰值温度260℃

Product No 1 2 3 4 5 6 7 8 9 10

patience high temperature OK OK OK OK OK OK OK OK OK OK

单项评价:符合规格书第7.2 项,合格。

轻触开关 >

TYPE-C连接器 >

关于我们 >

联系我们 >

电话:0769-82388879

传真:0769-81888689

地址:东莞市滨海湾新区信鸿欧菲光科创中心2号厂房701室

扫码咨询

公安备案号 : 44190002003787 粤ICP备18078670号 G-Switch 东莞品赞电子

品赞电子专业生产高质量轻触开关、防水轻触开关、轻触按键开关、Type-c连接器、防水Type-c母座等!电话:0769-82388879

技术支持:恒点互联