带认证无压柄长脚小微动开关

品牌:G-Switch/品赞

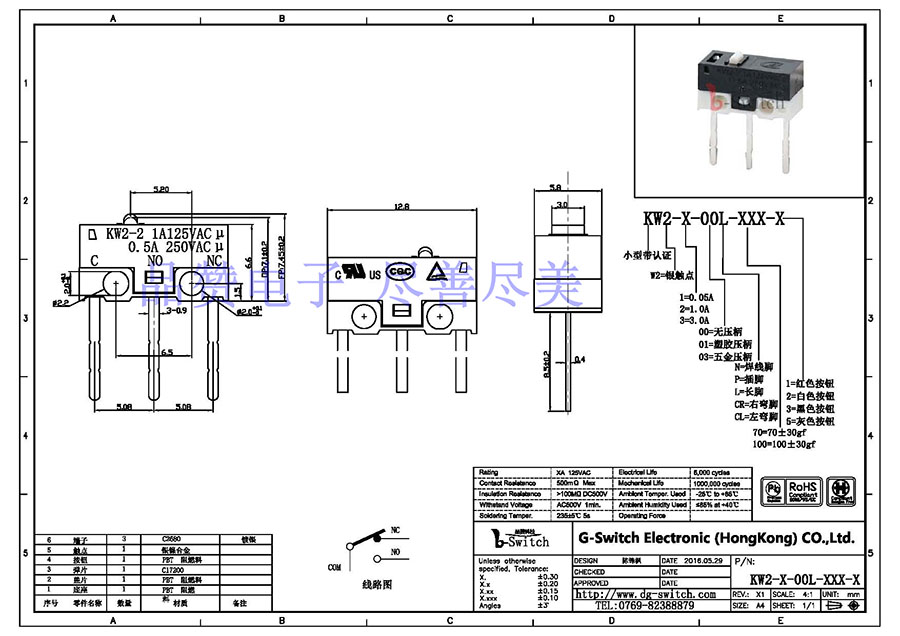

规格:12.8×5.8×6.6mm

型号:KW2-X-00L-XXX-X

包装:500/袋

声明:有关于产品的规格、参数、寿命、工作温度、手感、防水等级等数据,只代表品赞电子内部的测试结果,如需详细测试方式,请联系品赞业务人员。

基本说明

产品描述:

产品名称:带认证小微动开关

产品规格:12.8×5.8×6.6mm

产品压柄:无压柄

生产厂家:品赞/G-Switch

产品型号:KW2-X-00L-XXX-X

产品力度:100±30gf

产品电流:1.0A/3.0A

产品认证:UL、CQC、TUV

产品寿命:1000,000次

基本参数:

工作温度范围Operating temperature range:-30℃to+85℃

额定电流Rating:1.0A.125V AC

绝缘电阻Insulation resistance::100MΩ min.100V DC

介电强度Dielectric strength: 500V AC for 1 min

接触电阻Contact resistance::100m Ω max.

产品应用范围:

1、影音产品:MP3、MP4、DVD.音响;

2、数码产品:数码相机、数码摄像机等;

3、遥控器:车辆、点卷门、家庭防盗产品之遥控器;

4、通讯产品:手机、车载话机、电话机、楼宇设备、PDA等;

5、家用电器:电视机、微波炉、电饭煲、电风、电子人体秤、电子脂肪秤、电子厨房秤等;

6、安防产品:可视对讲机、监视器等;

7、玩具:电子玩具等;

8、电脑产品:摄像头、录音笔等;

9、健身器材:跑度机、按摩椅等;

10、医疗器材:血压计、体温计、医院呼叫系统等。

11、其他:验钞笔、雷射笔等。

产品名称:带认证小微动开关

产品规格:12.8×5.8×6.6mm

产品压柄:无压柄

生产厂家:品赞/G-Switch

产品型号:KW2-X-00L-XXX-X

产品力度:100±30gf

产品电流:1.0A/3.0A

产品认证:UL、CQC、TUV

产品寿命:1000,000次

基本参数:

工作温度范围Operating temperature range:-30℃to+85℃

额定电流Rating:1.0A.125V AC

绝缘电阻Insulation resistance::100MΩ min.100V DC

介电强度Dielectric strength: 500V AC for 1 min

接触电阻Contact resistance::100m Ω max.

产品应用范围:

1、影音产品:MP3、MP4、DVD.音响;

2、数码产品:数码相机、数码摄像机等;

3、遥控器:车辆、点卷门、家庭防盗产品之遥控器;

4、通讯产品:手机、车载话机、电话机、楼宇设备、PDA等;

5、家用电器:电视机、微波炉、电饭煲、电风、电子人体秤、电子脂肪秤、电子厨房秤等;

6、安防产品:可视对讲机、监视器等;

7、玩具:电子玩具等;

8、电脑产品:摄像头、录音笔等;

9、健身器材:跑度机、按摩椅等;

10、医疗器材:血压计、体温计、医院呼叫系统等。

11、其他:验钞笔、雷射笔等。

尺寸图

产品说明

|

1. 5General Characteristics 一般特性: 1.1 Application: This specification is applied to the micro switch (DM series) for general applications. 适用范围:该承认书指微动开关(DM系列)的一般使用范围。 1.2 Operating Temperature Range: -25℃to +65℃ 使用温度范围: -25℃to +65℃ 1.3 Operating Relative Humidity: ≤85% at +40℃ 相对湿度: ≤85% at +40℃ 1.4 Test Conditions: Unless otherwise specified, the atmospheric conditions for making measurements and tests are as follows: 实验条件:若没有特别说明,则试验大气条件如下: Ambient Temperature: 5~35℃ 环境温度: 5~35℃ Relative Humidity: 45~85% 相对湿度: 45~85% Air Pressure: 86~106Kpa (860~1060mbar) 大气压力: 86~106Kpa (860~1060mbar) |

|||

|

2. Appearance, Structure and Dimensions 外观,结构及尺寸: 2.1 Appearance: The switch shall have good finishing, and no rust, crack or plating defects. 外观: 产品外观良好,无锈蚀、裂纹和镀层缺陷。 2.2 Structure & Dimensions: Refer to individual product drawing. 结构及尺寸: 参见产品图纸 2.3 Markings: Refer to individual product drawing. 标识: 参见产品图纸。 |

|||

| 3. Ratings 额定负荷 | 10.1A 5A 125/250VAC | ||

| 4. Electrical Characteristics 电气特性 | |||

| No. | Item 项目 | Criteria 标准 | Test Method 实验方法 |

| 4.1 |

Contact Resistance 接触电阻 |

500mΩ Max. |

Measured by a voltage drop method at 0.1A Max, 12VDC. Any equipment with error not more than 5% can be used. Resistance after test is the average of 5 successive measurements. 以0.1A,12V直流电,采用电压降法测量。也可用误差不超过5%的仪表进行测量,实验后的电阻取5次测量的平均值。 |

| 4.2 |

Insulation Resistance 绝缘电阻 |

100MΩ Min. |

500VDC voltage is applied between each pair of terminals and between the terminal and the metal frame for 60±5S. 在相互绝缘的所有端子之间及各接线端子与外露的非载流金属零件之间加载500V直流电,持续时间60±5S。 |

| 4.3 |

Dielectric Voltage 抗电强度 |

No dielectric breakdown shall occur. 无击穿现象发生。 |

1500VAC (50~60Hz,cut –off current 2mA) is applied between non-connected terminals and between terminals and the metal frame for 60 ±5s. 在相互绝缘的所有接线端子之间1500V(50-60Hz)交流电,各接线端子与外壳或非载流金属零件之间加载1500V(50-60Hz)交流电,持续时间60±5S。 |

| 5. Mechanical Characteristics 机械特性 | |||

| 5.1 |

Operating Force 操作力 |

See product drawing 参见产品图纸 |

Apply a tension meter on the midpoint of the actuator (or tip of the shaft) to supply a pressure vertically from its free position to operating position. 在操作元件末端沿操作方向均匀施加静载荷,使操作元件转换到动作位置。 |

| 5.2 |

Return Force 回弹力 |

The value to which the force in the actuator midpoint (or tip of the shaft) must be reduced to allow the contact to the normal position. 在操作元件末端沿操作方向均匀减少静载荷,使操作元件从动作位置转换到自由位置。 |

|

| 5.3 |

Pre Travels 行程 |

The distance vertically through, which the midpoint of the actuator (or tip of the shaft) trip move from its free position to operating position. 从自由位置到动作位置的距离。 |

|

| 5.4 |

Solder Ability 可焊性 |

More than 80% of immersed part shall be covered with solder. 超过80%的浸锡面积被焊料所覆盖。 |

Switch shall be checked after following test: (1) Solder: H63A (JIS Z3282) (2) Flux: Rosin Flux (JIS K 5902) having a nominal composition of 25% solids by mass of water white rosin in methyl alcohol (JIS K 1501) solution. (3) Soldering Temperature: 235 ± 5°C Immersing Time: 3 ± 0.5s Flux immersing time shall be 5 ~10s in normal room temperature. (4) Immersion Depth: Immersion depth shall be at copper plating portion of PCB after mounting. (Thickness of PCB=1.6mm) 试件在下述参数条件下进行试验: ⑴ 焊料:H63A (JIS Z 3282) ⑵ 焊剂:焊剂(JIS K 5902),质量百分比为25%松香,75%甲醇的无色透明溶液。 ⑶ 焊接温度:235±5℃ 浸渍时间:3±0.5s 焊剂浸渍时间:5-10s ⑷ 浸渍深度:接线端应浸到离开关根部1.6mm处。 |

| 5.5 |

Solder Heat Resistance 耐焊接热 |

No abnormalities shall be observed in appearance and operation. The electrical performance requirements specified in item 4.3 shall be satisfied. 无外观及功能损坏。 电气性能应符合第4.3条的要求。 |

Switch shall be measured after following test: (1) Solder: H63A (JIS Z3282) (2) Flux: Rosin Flux (JIS K 5902) having a nominal composition of 25% solids by mass of water white rosin in methyl alcohol (JIS K 1501) solution. (3) Soldering Temperature & Immersing Time Dip Soldering 260±5℃ 5±1s Manual Soldering 300±5℃ 2~3s (4)Immersion Depth: (For Dip Soldering) Immersion depth shall be at copper plating portion of PCB after mounting. (Thickness of PCB=1.6mm) 试件在下述参数条件下进行试验: ⑴ 焊料:H63A (JIS Z 3282) ⑵ 焊剂:焊剂(JIS K 5902),质量百分比为25%松香,75%甲醇的无色透明溶液。 ⑶ 焊接温度及浸渍时间: 自动焊接 260± 5℃ 5±1s 手工焊接 300±5℃ 2~3s ⑷ 浸渍深度:(对于手动焊接) 接线端应浸到离开关根部1.6mm处。 |

| 5.6 |

Resistance to Flux 抗焊剂能力 |

Flux shall not be risen up to contact. The switch shall be free from abnormalities in operation. 焊剂不得上升进入开关内部,影响 接触转换。 试件在操作过程中不应发生变形。 |

Switch shall be checked after following test: (1) Equipment: Auto-Dip Chamber (2) Solder: H63A (JIS Z3282) (3) Flux: Rosin Flux (JIS K 5902) having a nominal composition of 25% solids by mass of water white rosin in methyl alcohol (JIS K1501) solution. (4) Soldering Temperature: 235 ± 5℃ (5) Immersing Time: 3 ± 0.5s (6) Immersion Depth: Immersion depth shall be at copper plating portion of PCB after mounting. (Thickness of PCB=1.6mm) 试件在下述参数条件下进行试验: ⑴ 设备:自动焊接机 ⑵ 焊料:H63A (JIS Z 3282) ⑶ 焊剂:焊剂(JIS K 5902),质量百分比为25%松香,75%甲醇的无色透明溶液。 ⑷ 焊接温度:235±5℃ ⑸浸渍时间:3±0.5s ⑹浸渍深度: 接线端应浸到离开关根部1.6mm处。 |

| 6. Durability characteristics | |||

| 6.1 |

Mechanical Life 机械寿命 |

After test, Contact resistance: 2Ω Max. Insulation resistance:50MΩ Min. The electrical performance requirements specified in item 4.3 shall be satisfied. The switch shall be free from abnormalities in appearance construction. 实验后: 接触电阻:2Ω Max. 绝缘电阻: 50MΩ Min. 电气性能应符合第4.3条的要求。 开关外观及结构应无损坏。 |

1,000,000 cycles of operation shall be performed continuously at a rate of 30 cycles per minute without load. 在不带负荷的条件下,速度为100次/分,在寿命试验设备上连续转换1,000,000次。 |

| 6.2 |

Electronics Life 电气寿命 |

10,000 cycles of operation shall be performed continuously at a rate of 30cycles per minute with load as follow 10.1A 125/250VAC 在带以下负荷的条件下,速度为8-10次/分,在寿命试验设备上连续转换10,000次。 10.1A 125/250VAC |

|

| 7. Weather Proof Characteristics 耐候性能: | |||

| 7.1 |

Cold Proof 低温 |

After test, Contact resistance: 2Ω Max. Insulation resistance: 50MΩ Min. The Electrical performance requirements specified in item 4.3 shall be satisfied. The switch shall be free from abnormalities in appearance &construction. 实验后: 接触电阻:2Ω Max. 绝缘电阻: 50MΩ Min. 电气性能应符合第4.3条的要求。 开关外观及结构应无损坏。 |

After testing at –20 ± 2°C for 96 hours, the switch shall be allowed to stand under normal temperature and humidity conditions for 1 hour, and measurement shall be made within 1 hour after that. Water drops shall be eliminated. 试件在-20±2℃的温控箱内保持96小时,然后在正常温度和湿度下恢复1小时,并在此后1小时内对试品进行测量,水滴应消失。 |

| 7.2 |

Hot Proof 高温 |

After testing at 85 ± 2°C for 96 hours, the switch shall be allowed to stand under normal temperature and humidity conditions for 1 hour, and measurement shall be made within 1 hour after that. 试件在85±2℃的温控箱内保持96小时,然后在正常温度和湿度下恢复1小时,并在此后1小时内对试品进行测量,水滴应消失。 |

|

| 7.3 |

Moisture Resistance 恒定湿热 |

After testing at 40± 2°C ,90~95% RH for 96 hours, the switch shall be allowed to stand under normal temperature and humidity conditions for 1 hour, and measurement shall be made within 1 hour after that. Water drops shall be eliminated. 试件在40±2℃,90-95%RH的温控箱内保持96小时,然后在正常温度和湿度下恢复1小时,并在此后1小时内对试品进行测量,水滴应消失。 |

|

- 上一篇:短脚无压柄微动开关

- 下一篇:带认证无压柄右弯脚小微动开关

轻触开关 >

TYPE-C连接器 >

关于我们 >

联系我们 >

电话:0769-82388879

传真:0769-81888689

地址:东莞市滨海湾新区信鸿欧菲光科创中心2号厂房701室

扫码咨询

公安备案号 : 44190002003787 粤ICP备18078670号 G-Switch 东莞品赞电子

品赞电子专业生产高质量轻触开关、防水轻触开关、轻触按键开关、Type-c连接器、防水Type-c母座等!电话:0769-82388879

技术支持:恒点互联