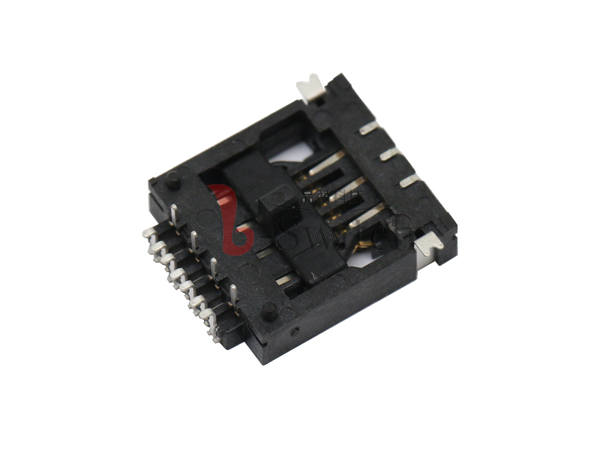

14P血糖仪试纸连接器 带推柄带柱

品牌:G-Switch/品赞

规格:12.38×11.3×3.35mm

型号:SK-0008S00

包装:500/卷

声明:有关于产品的规格、参数、寿命、工作温度、手感、防水等级等数据,只代表品赞电子内部的测试结果,如需详细测试方式,请联系品赞业务人员。

基本说明

产品描述:

产品名称:血糖仪试纸连接器

产品尺寸:12.38×11.3×3.35mm

产品性能:14P 试纸连接器 带推柄

生产厂家:品赞/G-Switch

产品型号:SK-0008S00

产品寿命:10,000次

基本参数:

额定负荷 Rating :DC16V 0.3A

接触电阻 Contact Resistance :50mΩMAX

绝缘阻抗 Insulation Resistance: 100MΩMIN

适用温度 Ambient Temper.Used: -25 ℃ to 85 ℃

耐高压 Withstand Voltage :AC 500V(50-60HZ) 1min

适用湿度 Ambient Humidety Used :85% RH

焊接温度 Soldering Temper :265±5°10s

插拔力 Operating Force: 3-30N

产品名称:血糖仪试纸连接器

产品尺寸:12.38×11.3×3.35mm

产品性能:14P 试纸连接器 带推柄

生产厂家:品赞/G-Switch

产品型号:SK-0008S00

产品寿命:10,000次

基本参数:

额定负荷 Rating :DC16V 0.3A

接触电阻 Contact Resistance :50mΩMAX

绝缘阻抗 Insulation Resistance: 100MΩMIN

适用温度 Ambient Temper.Used: -25 ℃ to 85 ℃

耐高压 Withstand Voltage :AC 500V(50-60HZ) 1min

适用湿度 Ambient Humidety Used :85% RH

焊接温度 Soldering Temper :265±5°10s

插拔力 Operating Force: 3-30N

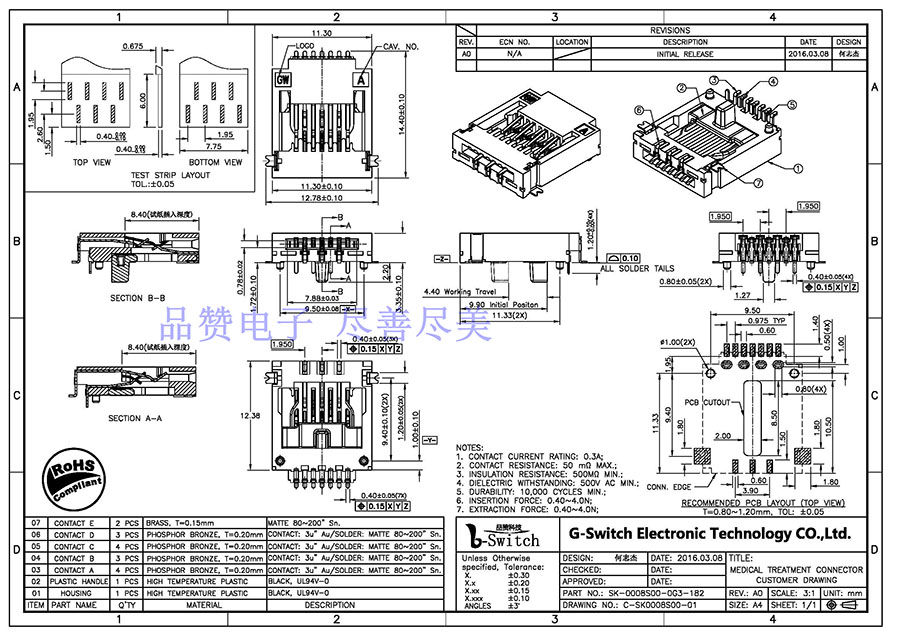

尺寸图

产品说明

| 文件编号 DOC NO.: | 版本 VERSION: | 编写日期 DATE: | 编写 WRTN: | 审核 CHKD.: | 批准 APPO.: | |||||

| GWS-023 | A | 2010.10.27 | ||||||||

| MODEL TYPE: | MEDICAL TREATMENT CONNECTOR | 李海鸥 | ||||||||

| 产品类型: | ||||||||||

| PART NO.: | ||||||||||

| 产品编号: | ||||||||||

| 1. SCOPE 适用范围 | ||||||||||

| This specification covers the performance, tests and quality requirements for “MEDICAL TREATMENT CONNECTOR ”。 | ||||||||||

| 本产品规范包涵了 “MEDICAL TREATMENT CONNECTOR ” 的性能、测试和品质要求。 | ||||||||||

| 2. APPLICABLE DOCUMENTS 使用说明 | ||||||||||

| In the event of conflict between the requirements of the specification and product drawing, the product drawing shall take | ||||||||||

| precedence, In the event of conflict between the requirements of the specification and the referenced documents, the | ||||||||||

| specification shall take precedence. | ||||||||||

| 如果产品规范和产品图发生冲突时,以产品图为准;如果产品规范和相关参考文件发生冲突时,以产品规范为准。 | ||||||||||

| 3. PRODUCT DESCRIPTION 产品描述 | ||||||||||

| 3.1 Design And Construction 设计和结构 | ||||||||||

| Product shall be of the design, construction and physical dimensions specified on the applicable product drawing. | ||||||||||

| 产品需符合产品图面规定的设计,结构和尺寸要求。 | ||||||||||

| 3.2 Material and Plating 材料和电镀 | ||||||||||

| Refer to respective Getwell product drawings for information on materials, plating and marking; Solder component shall | ||||||||||

| meet lead-free soldering requirements and the connectors shall be RoHS compliant. | ||||||||||

| 相关的材料,电镀等信息请参照皓威的产品图面;焊接件需满足无铅焊接要求,产品需符合RoHS标准。 | ||||||||||

| 4. REQUIREMENTS 必要条件 | ||||||||||

| 4.1 Rating 额定值 | ||||||||||

| Rated Voltage (Max) 额定电压:30V DC | ||||||||||

| Rated Current (Max) 额定电流:0.5A | ||||||||||

| Operating Temperature Range 工作温度范围:-20~+80℃ | ||||||||||

| Operating Humidity Range 工作湿度范围:95%H.R.Max. | ||||||||||

| Standard test conditions shall be 5 to 35℃ in temperature and 45 to 85% in humidity and 86kPa to 106kPa air pressure. | ||||||||||

| 在温度为 5~35℃,湿度45~85%,86kPa~106kPa 大气压强的标准状态下进行实验测试。 | ||||||||||

| 4.2 Performance and Test description 功能及测试条件描述 | ||||||||||

| The connectors shall be designed to meet the electrical, mechanical and environmental performance requirements specified | ||||||||||

| as belows. 产品的设计应满足如下电气,机械,及环境特性需求。 | ||||||||||

| 5. TEST REQUIREMENTS AND PROCEDURES SUMMARY 测试要求和程序概要 | ||||||||||

| NO. | Test items 项目 | Requirments 规格要求 | Condition and Test method 条件和测试方法 | |||||||

| 5-1 |

Examination of product 外观检查 |

No physical damage 无明显的物理损坏 |

EIA-364-18A. Visual inspection. 目视检查。 |

|||||||

| PAGE 1 OF 4(第1页,共4页) | ||||||||||

| NO. | Test items 项目 | Requirments 规格要求 | Condition and Test method 条件和测试方法 | |||||||

| Electronical characteristic 电气性能 | ||||||||||

| 5-2 |

Contact resistance 接触阻抗 |

100mΩ Max. 100毫欧以下。 |

EIA 364-23A Subject mated contacts assembled in housing to be measured at 1KHz, 20mV Max. open circuit at 100 mA Max. by contact resistance meter. 将端子组装在塑胶体中,用阻抗仪器在1KHz, 最大20mV的开路电压和100mA的电流条件下进行测量。 |

|||||||

| 5-3 |

Insulation resistance 绝缘阻抗 |

100MΩ Min.. 100兆欧以上。 |

EIA 364-21B Insert plug gauge into the specimen, apply 300V DC for 1 minute between adjacent terminals. 样品插入插头,对相邻端子之间加 300V DC,并持续1分钟进行测量。 |

|||||||

| 5-4 |

Dielectric Withstanding Voltage 耐电压 |

No flashover or insulation breakdown 无跳火或绝缘体击穿现象。 |

EIA 364-20A Apply 300V AC (50Hz or 60 Hz) between adjacent terminals or ground for 1 minute. 在相邻端子之间之间加 300V AC (50Hz or 60 Hz),并持续1分钟。 |

|||||||

| Mechanical characteristic 机械性能 | ||||||||||

| 5-5 |

Insertion and extraction force 插入&拔出力 |

Insertion force: 插入力度:0.25N-5N Extraction force: 拔出力度:0.25N-5N |

EIA 364-13A Insertion and extraction force shall be measured after inserting and withdrawing 3 times by using a plug gauge, and then measure the insertion and extraction force. Mating/unmating at a rate of 12.5mm per minute. 用插头插拔3次后,测量其插入和拔出的作用力。插入或拨出速度为每分钟12.5mm。 |

|||||||

| 5-6 |

Durability 插拔耐久 |

(1) Appearance: No breakdown; (2) Insertion & extraction force and Electrical characteristic shall be satisfied. (3)Contact resistance:150mΩ Max (1) 外观无损坏; (2) 插拔力和电性能安全。 (3)接触电阻:150毫欧以下 |

EIA 364-09B Inserting and withdrawing up to 100000 cycles repeatedly at the rated of between 15 and 18 cycles per minute. 每分钟插拨15次至18次,重复插拨100000次以上。 |

|||||||

| Enviromental characteristic 环境性能 | ||||||||||

| 5-7 |

Solder-ability 可焊性 |

(1) Above 95% of immersed area show no voids or pin holes (1)粘锡面积至少95%以上 |

EIA 364-52 Dip solder-tails in flux then immerse in bath at 245±5℃ up to 0.5mm from the bottom of the housing for 4~5s 将锡脚浸到熔炉焊剂当中,温度为245±5℃,浸入 深度至少0.5mm,时间4~5秒 |

|||||||

| PAGE 2 OF 4(第2页,共4页) | ||||||||||

| NO. | Test items 项目 | Requirments 规格要求 | Condition and Test method 条件和测试方法 | |||||||

| 5-8 |

Resistance to soldering heat 耐焊锡性热 |

(1)Without any deformation of case or excessive losseness of the pins.Electrical characteristics shall be satisfied (1)外观无变形,端子无松 动,并满足电气特性需求 |

Solder bath method锡炉焊锡方法: Solder temperature焊锡温度:260±5℃ Immersion time浸炉时间:10±1s Solder iron method手工烙铁焊锡方法: Solder temperature焊锡温度:350±10℃ Immersion time焊锡时间:3±1s Excessive pressure shall not be applied to the terminal不能有额外的压力施加于端子上 |

|||||||

| 5-9 |

Resistance to heat 耐热 |

(1) Contact resistance: 150 mΩ Max (2) Insulation resistance: 50 MΩ Min. (3)Withstand voltage500V AC(50Hz or 60Hz) (4)There shall be no sign of damage mechanically and electrically. (1)接触电阻:150毫欧以下 (2)绝缘阻抗:50兆欧以上 (3)耐电压:AC 500 (4)无击穿现象及任何迹象显示机械及电气性能损坏。 |

EIA 364-17B 80±2℃ for 96 hours, test after keeping in normal condition for 30 minutes. 在80±2℃环境中放96小时,再放在正常环境中,30分钟后进行测试。 |

|||||||

| 5-10 |

Humidity test 恒温恒湿 |

EIA 364-31 40±2℃ 90-95%RH for 96 hours, test after keeping in normal condition for 30 min. 在40±2℃ 90-95%RH 环境中放96小时,再放在正常环境中30分钟后进行测试。 |

||||||||

| 5-11 |

Resistance to cold 耐冷 |

EIA 364-17B At -20±2℃ for 96 hours, test after keeping in normal condition for 30 min. 在-20±2℃环境中放96小时再放在正常环境中30分钟后进行测试。 |

||||||||

| 5-12 |

Salt spray 盐水喷雾 |

(1)Appearance:No noticeable rust and other physical damage (2)Contact resistance:50mΩ Max (1)外观:无明显锈迹及其它的物理损坏 (2)接触电阻:150mΩ最大 |

EIA 364-26 Mate plugs and expose to the following sal mist conditions.Upon completion of the exposure period,salt deposits shall be removed by a gentle wash or dip in running water,after which the specified measurements shall be performed.将公头插入并暴露于下面盐雾条件,这个过程完成后,沉积的盐粒要用软刷刷掉,并用流水冲洗干净,这些完成后,才能做相关指定的测试 NaCl solution氯化钠熔液 Concentration浓度:5±1% Spray time喷雾时间:24H Ambient temperature周围温度:35±2℃ |

|||||||

| PAGE 3 OF 4(第3页,共4页) | ||||||||||

| NO. | Test items 项目 | Requirments 规格要求 | Condition and Test method 条件和测试方法 | |||||||

| 5-13 |

Resistance to Reflow Soldering Heat 耐回流焊热 |

(1) Tested housing shall show no evidence oflosseness of deformation or fusion of housing and no physical damage. (1) 测试塑胶无变形,熔化 |

Pre-Heat 预热150~170°C: 60~120sec Heat加热220+/-10°C: 60sec. Min. Heat Peak 峰值260+/-5°C: 10sec. Max. (See FIG 1.) |

|||||||

|

||||||||||

东莞品电子科技有限公司开发、设计、生产:血糖仪试纸连接器5P、试纸接口连接器4P、9P试纸连接器、8P试纸连接器、7P试纸连接器等血糖仪试纸连接器。

- 上一篇:8P血糖仪试纸连接器 无推柄带柱

- 下一篇:血糖仪试纸连接器8P 带推柄

推荐产品

轻触开关资讯

拨动开关资讯

检测开关资讯

轻触开关 >

TYPE-C连接器 >

关于我们 >

联系我们 >

电话:0769-82388879

传真:0769-81888689

地址:东莞市滨海湾新区信鸿欧菲光科创中心2号厂房701室

扫码咨询

公安备案号 : 44190002003787 粤ICP备18078670号 G-Switch 东莞品赞电子

品赞电子专业生产高质量轻触开关、防水轻触开关、轻触按键开关、Type-c连接器、防水Type-c母座等!电话:0769-82388879

技术支持:恒点互联